ForgeFab Tips & Insights

Guides, code insights, pricing explanations, and practical advice for metal building owners, contractors, and DIY builders.

A Practical Construction-Phase Strategy for Temporary Equipment Access

When industrial or utility buildings are being constructed—especially electrical shelters, dosing buildings, and pump-station enclosures—contractors often face the same challenge:

Large equipment needs to be moved inside before the building is fully enclosed.

But once construction is complete, that large opening is no longer needed.

Traditionally, project teams solve this by installing a temporary roll-up door or even specifying a wind-rated overhead door that ends up being used only during the early stages of construction. This approach creates unnecessary cost, introduces submittal complications, and can even delay the project when specialized doors don’t arrive on time.

Fortunately, there is a better way.

The Problem With Wind-Rated Doors for Temporary Use

For permanent industrial structures, exterior roll-up doors generally must be rated for the project’s design wind loads. That means:

- Higher material cost

- Longer lead times

- Additional framing requirements

- Engineering reviews

- More complex installation

- Potential delays if the door isn't approved or delivered on time

And in many cases, the door is only used during construction, then removed or walled in later.

Utility buildings simply don’t need a permanent roll-up door if the opening is only for placing equipment.

A Better Approach: Engineer the Building Fully Enclosed and Sequence the Opening Temporarily

Instead of designing the building around a roll-up door, the better solution is to:

1. Engineer the building as a fully enclosed structure

The building manufacturer designs all walls, girts, and base angles in their

final, fully enclosed configuration.

This ensures:

- Full code compliance

- Wind-rated performance

- No changes to the stamped drawings

- No special door engineering

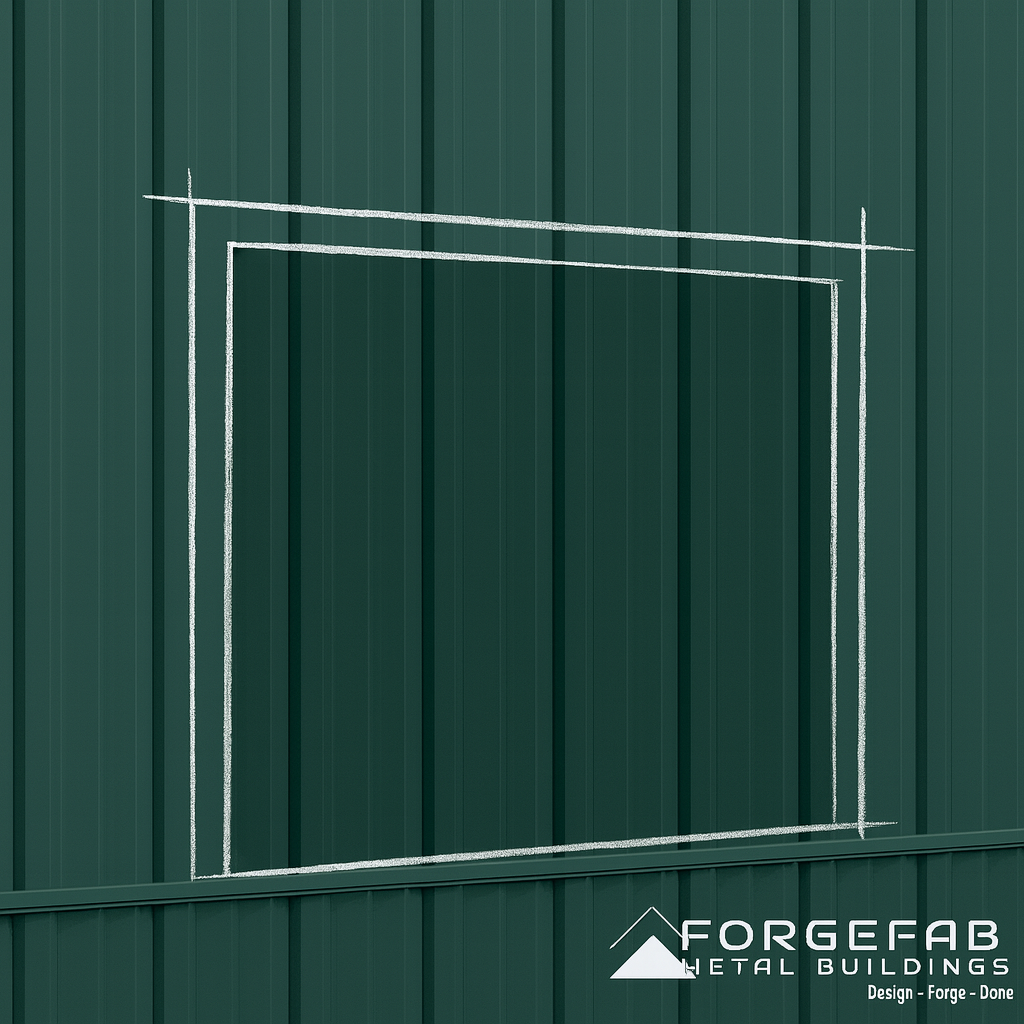

2. During erection, leave out a single girt and a small section of base angle

These components create a temporary opening large enough to move in electrical equipment, skids, pumps, chemical dosing panels, or MCC/PLC cabinets.

The structure remains stable because the final engineered condition is unchanged—you’re simply installing these components later in the sequence.

3. Allow the general contractor to install any temporary access method they choose

This could be:

- A low-cost non-rated roll-up door

- A vinyl curtain

- Plywood blocking

- A temporary framed barrier

No special engineering or submittals are needed because the temporary condition is the contractor’s responsibility, not the building supplier’s.

4. After equipment is inside, install the remaining girt and base angle

Once equipment placement is finished:

- The missing components are installed in their engineered locations

- Wall panels are installed per the stamped drawings

- The building becomes fully enclosed exactly as designed

No changes. No redesign. No deviations from the approved plans.

Why This Method Makes Sense

✔ Avoids the need for a wind-rated door

You save the project significant cost and avoid procurement delays.

✔ Maintains structural integrity and code compliance

Because the building is engineered as fully enclosed, the PE-sealed system never changes.

✔ Simplifies submittals

No door specifications, wind certifications, or structural reactions to coordinate.

✔ Faster project sequencing

Equipment can be placed earlier in the construction timeline.

✔ Cleaner close-out

No unused doors. No warranty items. No long-term maintenance concerns.

✔ Perfect for electrical, mechanical, and utility enclosures

This approach is ideal for water treatment facilities, pump stations, SCADA/MCC rooms, and utility shelters—anywhere equipment needs to be placed prior to finishing the wall system.

Where This Approach Works Best

- Municipal and industrial electrical shelters

- Chemical dosing buildings

- Pump and blower enclosures

- Water treatment utility shelters

- Prefabricated metal buildings with one-time access needs

- Any structure where equipment is installed before building completion

Conclusion

When project teams need temporary large openings during construction, they don’t have to rely on expensive wind-rated roll-up doors. By engineering the building as a fully enclosed structure and sequencing one girt and base angle to be installed later, you create a safe, code-compliant, and highly efficient access strategy.

It reduces cost, streamlines submittals, speeds up construction, and eliminates long-term complications.

Utility contractors, engineers, and procurement teams benefit from simpler logistics—and the final building stays exactly as it was designed.